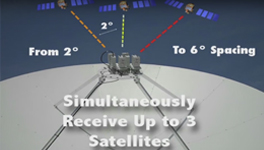

ACCESS 3 SATELLITES OVER 6°

Access 3 satellites over 6° of arc coverage with outstanding video response. Typical configuration may receive IA-13, G10R, G14(12), G13 and IA7.

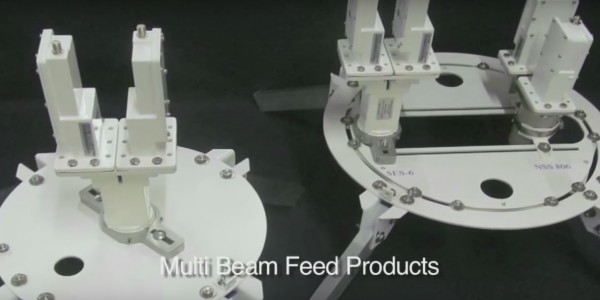

MULTIPLE SATELLITE FEED FEATURES:

Multi-Sat performance kits designed for ease of installation & maximum flexibility

Feature discreet azimuth, elevation, focal length and polarization adjustments

Available for all commercial satellite antennas

Simultaneous reception of up to 5 adjacent satellites

Factory Pre Set & Look Angles provided to speed alignment

System includes support struts, feed plate assembly, feed horns and cover.

Does NOT include LNBs.

OVERVIEW

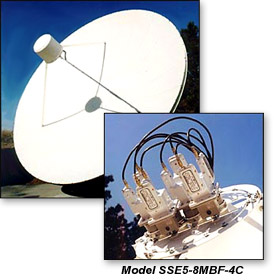

In 1983, with input from Hughes Communications engineer Norm Weinhouse, Superior Satellite Engineers developed the multi-beam feed system to provide access to multiple satellites from a single antenna. We are not only the pioneers of this technology, but by far the industry leaders with delivery of over 20,000 systems world wide.

Our years of experience have familiarized us with the performance characteristics of virtually every commercial satellite antenna. This assures that our multi-beam feed system and recommended alignments will provide adequate satellite reception.

APPLICATIONS

The Superior Satellite multi-feed system is designed for C and/or Ku band applications with the flexibility of satellite orientations from 2 degrees to 8 degrees spacing. Each system is custom built for your specific antenna and required satellite alignment with easy to follow placement instructions for correct focal distance. We utilize a relatively small diameter system to minimize signal loss due to shadowing. Each feed system is pre-oriented at the factory to your specific location with regard to feed spacing and declination angle for ease of installation and alignment.

COMPONENTS

Feed assembly – Our system features a unique feed assembly design which allows for discrete elevation and azimuth adjustment of off boresight feeds without regard to the orientation of the mounting struts on the antenna. This is achieved using an outer ring for strut mounting and an inner slotted feed plate. The inner plates rotate in the outer ring to provide off boresight elevation adjustment . The feedhorn assemblies slide side to side in the slotted inner feed plate to provide off boresight azimuth adjustment. The entire assembly features a powder coat finish for rust prevention and other environmental protections. The feed system is manufactured from 3/16″ aluminum plate to provide a light weight, sturdy corrosion resistant platform.

Feed horns – For dual pole C Band reception we feature Chaparral’s Model 1329. With 35 dB of cross pole isolation and an extremely low failure rate, it has become an industry standard. It is mounted in clamp assembly which provides polarity and focal length adjustment.

Support struts – We now supply rectangular aluminum tubing for support struts, pre-cut and drilled. This is probably our biggest improvement in our system since its original design. System stability and aesthetics have been improved dramatically. The struts are significantly lighter for reduced shipping costs and ease of installation.

Cover – Another recent system upgrade is our injection molded cover. It is light weight, yet rigid and durable, constructed of high quality plastic with U/V stabilizer for long life in high wind environments.

APPLICATIONS

It should be noted first of all that replacing your original feed system with our multi beam retro-fit will not degrade your signal levels of “on boresight” satellites. It should also be noted if you are replacing a “cassegrain” styled feed system, you should expect better “on boresight” performance.

In a typical multi beam scenario (2,3 or 4 feeds), you would have one feed on or near boresight with no signal loss. Conservative estimates of adjacent feeds “off boresight” loss (at C/N and S/N) are as follows:

- at 2 degrees off boresight = .75 dB Loss

- at 3 degrees off boresight = 1 dB Loss

- at 4 degrees off boresight = 2 dB Loss

We have a complete testing facility at our plant in Columbia Falls, Montana. With a wide range of antenna sizes available, we can test your customer’s particular configuration and provide them with accurate and comprehensive test data.